Technical / White Paper

Keeping production moving with wash-down screens

Production schedules and processes on any site are always susceptible to change, either sudden or planned. All businesses find themselves driven to change either by forces outside of their control such as a change in legislation or technology, or at one point or another, systems will need to be, examined, analysed and rethought in order for a company to progress. A corporation that evaluates and re-examines its production methods on a regular basis will naturally find itself competing with the very best, and offering the highest possible standards. When a business decides to revamp its production systems, Westgate can step in to provide high-quality segregation solutions, all installed with minimal downtime.

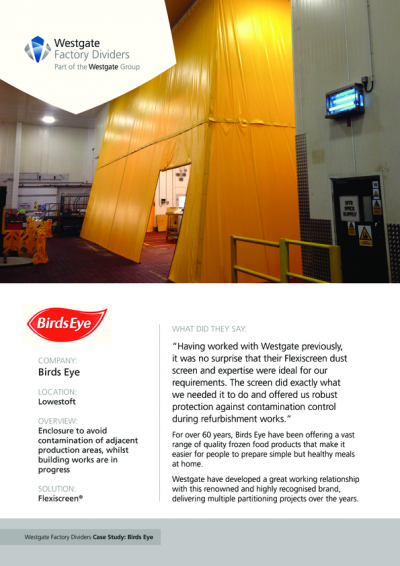

As discussed, no business is or has been without change in their sites production methods, even a corporation as big as Birds Eye. In March 2016, Birds Eye Lowestoft wanted to ensure that there was no potential for cross contamination between different product types during its planned and scheduled wash-downs. Representatives from the company contacted Westgate for assistance.